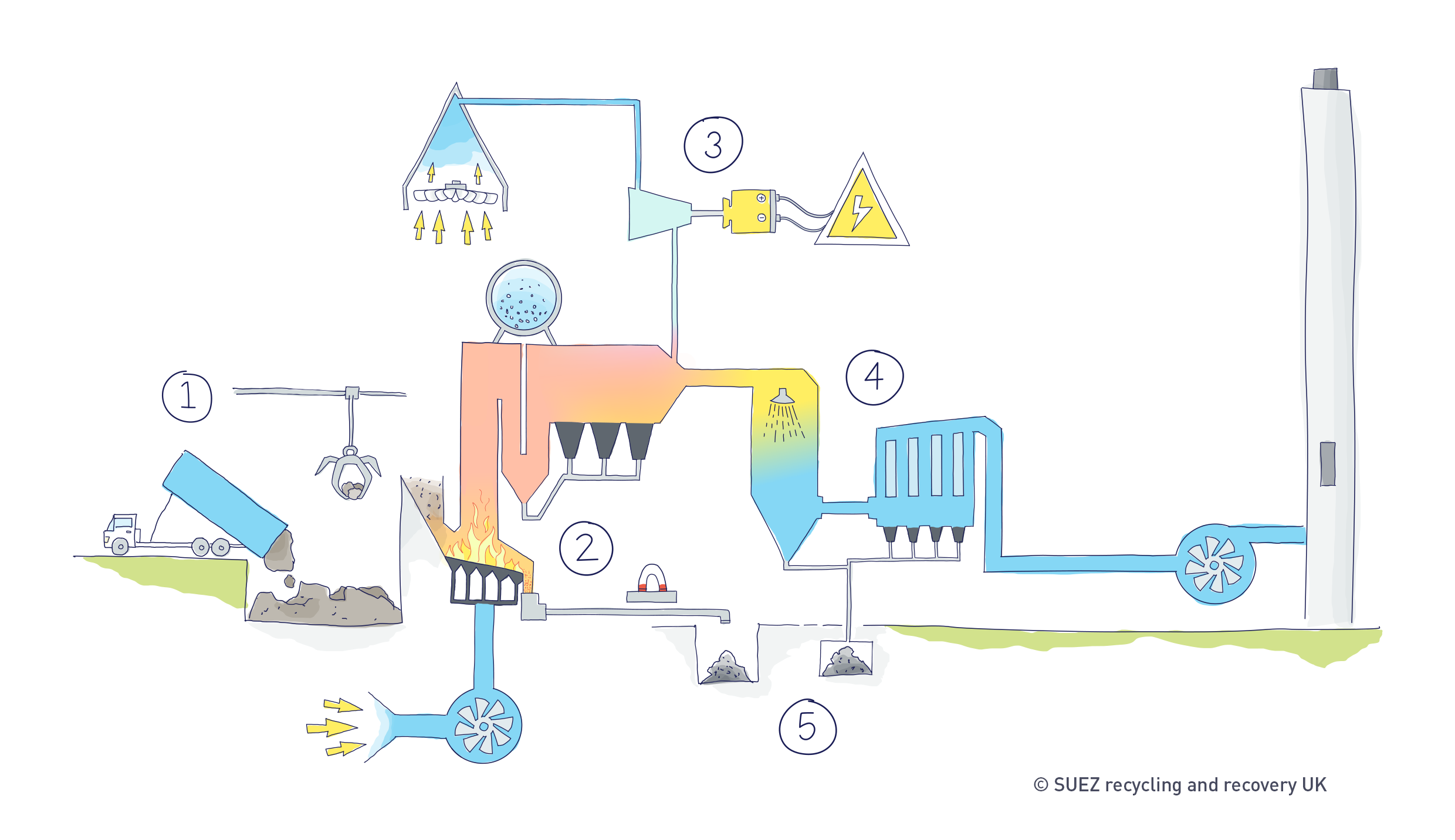

How does energy-from-waste work?

Where

mixed wastes remain after recycling, or it is not practicable to

reclaim the materials, the energy value of these resources can be

recovered safely, using modern energy-from-waste technology.

1. Collection

Waste collection vehicles enter the reception hall of our energy-from-waste facility and discharge their waste into a bunker. A grab crane operator mixes the waste to ensure an even burn in the furnace. Water sprays and induction fans in the reception hall reduce the levels of dust and odours.

2. Incineration

The crane loads the mixed waste into a feed hopper, and it travels down a chute into the furnace. Inside the furnace, a series of grate bars move the waste through the furnace where it dries and burns at temperatures of around 1000°C. Burning the waste creates a hot flue gas – which is used as a source of renewable energy – and incinerator bottom ash, which can be used in construction.

3. Energy generation

The hot flue gases travel through a boiler, heating water that runs through boiler pipes. This turns into steam that drives a turbine, generating electricity.

4. Emissions

The gases from the burned waste are cleaned thoroughly. Lime is used to neutralise acidic gases and carbon to remove dioxins and heavy metals. The gas then passes through a fine fabric filter to capture any remaining particles before it is released through a chimney.

5. Other by-products

The incinerator bottom ash from burnt waste drops into a quench tank and then passes along a conveyor to a storage pit. Magnets above the conveyor extract ferrous metals from the ash for recycling. The ash then goes to an ash recycling plant, so it can be used as an aggregate replacement in construction materials.

Waste collection vehicles enter the reception hall of our energy-from-waste facility and discharge their waste into a bunker. A grab crane operator mixes the waste to ensure an even burn in the furnace. Water sprays and induction fans in the reception hall reduce the levels of dust and odours.

2. Incineration

The crane loads the mixed waste into a feed hopper, and it travels down a chute into the furnace. Inside the furnace, a series of grate bars move the waste through the furnace where it dries and burns at temperatures of around 1000°C. Burning the waste creates a hot flue gas – which is used as a source of renewable energy – and incinerator bottom ash, which can be used in construction.

3. Energy generation

The hot flue gases travel through a boiler, heating water that runs through boiler pipes. This turns into steam that drives a turbine, generating electricity.

4. Emissions

The gases from the burned waste are cleaned thoroughly. Lime is used to neutralise acidic gases and carbon to remove dioxins and heavy metals. The gas then passes through a fine fabric filter to capture any remaining particles before it is released through a chimney.

5. Other by-products

The incinerator bottom ash from burnt waste drops into a quench tank and then passes along a conveyor to a storage pit. Magnets above the conveyor extract ferrous metals from the ash for recycling. The ash then goes to an ash recycling plant, so it can be used as an aggregate replacement in construction materials.