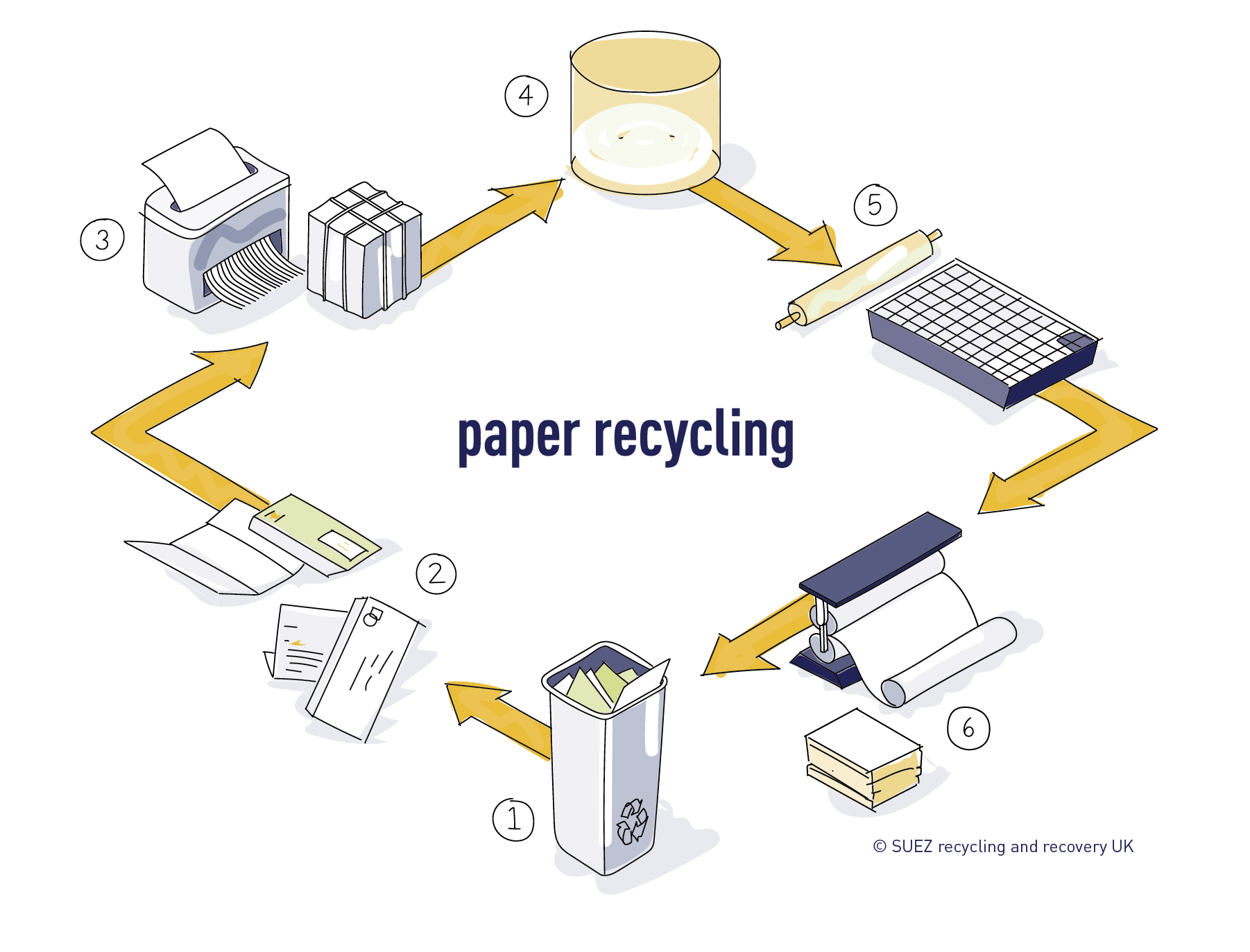

What happens to paper?

1. Collection

Waste paper is collected for recycling from people’s homes, recycling sites and businesses.

2. Sorting and grading

Before it can be recycled, collected paper must be sorted and graded; there are over 50 grades of waste paper.

The four main groups are:

- Low grade – i.e. mixed paper, corrugated board

- De-inking grade – i.e. newspapers, magazines, office paper

- Kraft grade – i.e. unbleached brown packaging

- High grade – i.e. printer cut-offs, unprinted paper

3. Shredding and baling

Many businesses, offices and some homes shred documents to protect sensitive information. Companies (like SUEZ) provide a confidential shredding service to ensure that documents are collected and shredded securely. Large amounts of graded paper, including shredded paper, are compressed by a machine into a bale shape before being transported to a paper mill.

4. Pulping, screening and de-inking

At the paper mill, the graded paper is placed in a large vat and mixed with water. This process breaks down the paper into tiny strands of cellulose (organic plant material) fibres. Eventually, this turns into a mushy mixture called pulp. The pulp is then filtered and screened to remove contaminants such as glue and bits of plastic.

For certain uses, pulp must also be de-inked. There are two main methods of de-inking:

- Washing – Chemicals are used to separate the ink from the paper, and then washed away with water. The quantities of chemicals and water used are much less than in the manufacture of new paper, and the water can often be cleaned and reused.

- Flotation – Air passed through the pulp produces foam, which absorbs the ink and can be skimmed off. This may be repeated or combined with a washing process to remove all the remaining ink.

5. Drying

Pulp is poured onto a huge, flat wire screen. On the screen, water starts to drain from the pulp and the recycled fibres soon bond together to form a watery sheet.

The sheet, which now resembles paper, passes through a series of heavy rollers. These squeeze out more water, while some heated cylinders dry the paper, and another roller irons it.

6. Rolling

Now the paper is wound into a giant roll, which can be as wide as 30 feet and weigh 20 tonnes. The roll is cut into smaller rolls, or sometimes sheets, before being ready for use.