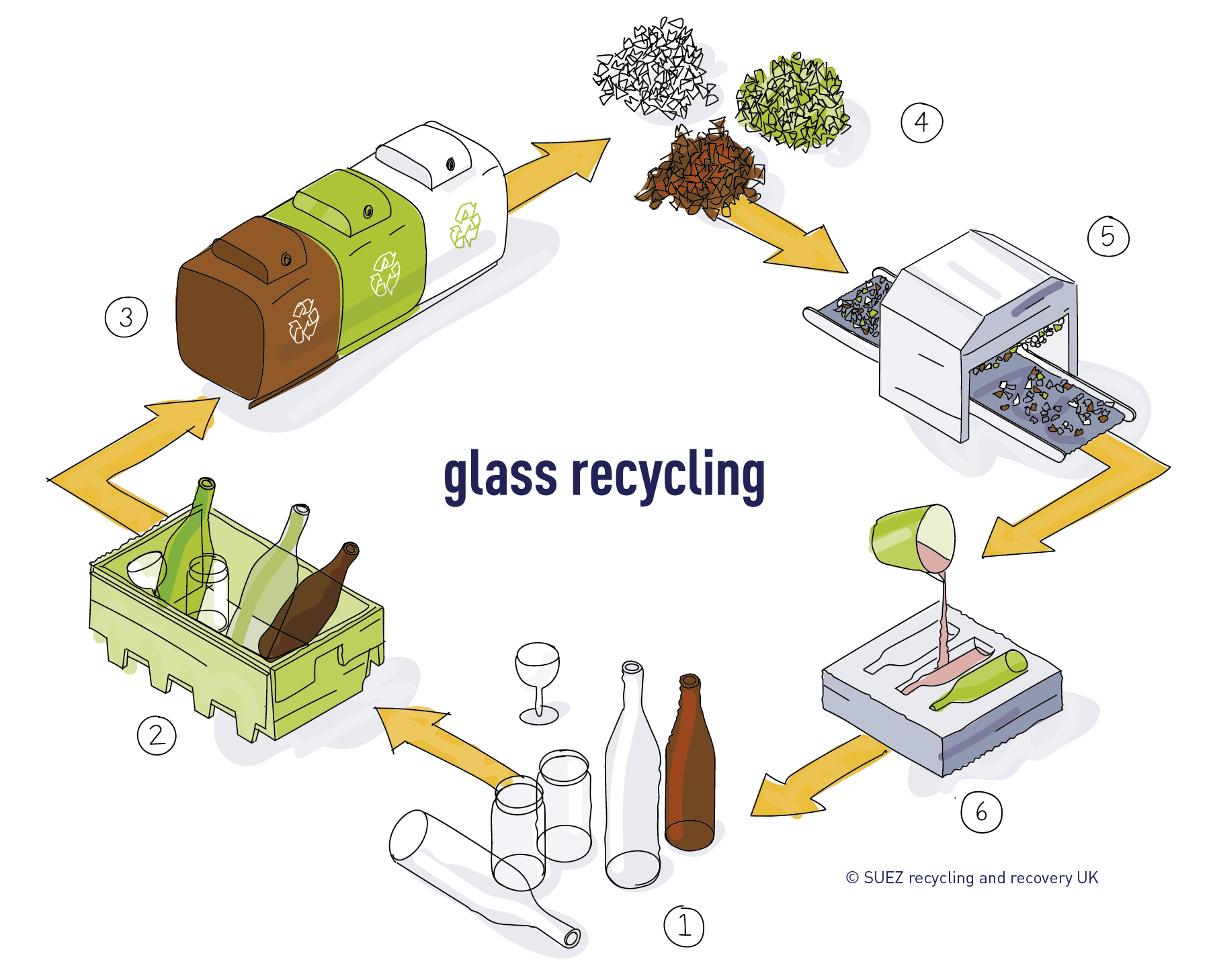

What happens to glass?

1. Types of glass

Different types of glass require different recycling processes. For example, cookware (like Pyrex dishes) must be melted at a much higher temperature than container glass and processed separately.

The main types are:

- Container glass – e.g. jam jars, wine bottles, beer bottles

- Float glass – e.g. windows, flat glass

- Cookware – e.g. Pyrex dishes, tableware (plates, wine glasses)

- Automotive glass – e.g. windscreens

Overall, compared with manufacturing of new glass, recycling saves 30% of the energy as this glass is melted at a lower temperature.

2. Collection

Glass is collected for recycling from people’s homes, recycling sites and businesses. Most glass comes from businesses, such as bars and restaurants, and bottle banks.

3. Sorting

If different colours of glass are mixed together, they are separated before being processed.

4. Crushing

At a glass recycling facility, the glass is crushed to form what’s called cullet. Cullet is mostly used to make new glass, but it can be crushed further into a powder used as a substitute for stone aggregates in building roads.

5. Cleaning

Cullet goes through many processes to remove items that are not glass:

- A strong magnet picks up ferrous (magnetic) metals such as steel and iron

- Powerful air jets move non-ferrous (not magnetic) metal pieces away from the cullet

- Passing through a vacuum separates lightweight items (like paper)

- Any remaining non-glass items (like ceramics), are ejected by a laser

6. New glass

Once cleaned, the cullet is now ready to be made into new glass. Glass cullet is melted in a furnace at a temperature of 1500°C to form a liquid or molten glass. The molten glass is shaped in moulds to become new bottles or jars.